Essentials to Know About Custom Metal Fabrication

Fabricated metal products are becoming popular by the day due to their diverse applications. Even so, few people know how the metal fabrication process works. Custom metal fabrication involves replicating any generic metal product in functionality and look. The process is used to create architectural materials, structural metals, cutlery, and hand tools. Here are some essentials that you need to know about custom metal fabrication:

Custom Metal Fabrication is a Centuries-Old Technology

Human beings have created and used metal products for centuries. Therefore, custom metal fabrication is one of the earliest technologies used by human beings. Iron, gold, tin, silver, mercury, copper, and lead were the primary metals used in ancient societies. Metalworking technologies such as forming, cutting, and joining were common. Blacksmiths were among the most prominent and revered members of society.

Leonardo da Vinci sketched a rolling mill in 1485, and this sketch was later used to create a press for rolling gold sheets into coins. During the Industrial Revolution, metal fabrication became even more popular due to the development of different metallic products.

You Can Create Everything Imaginable

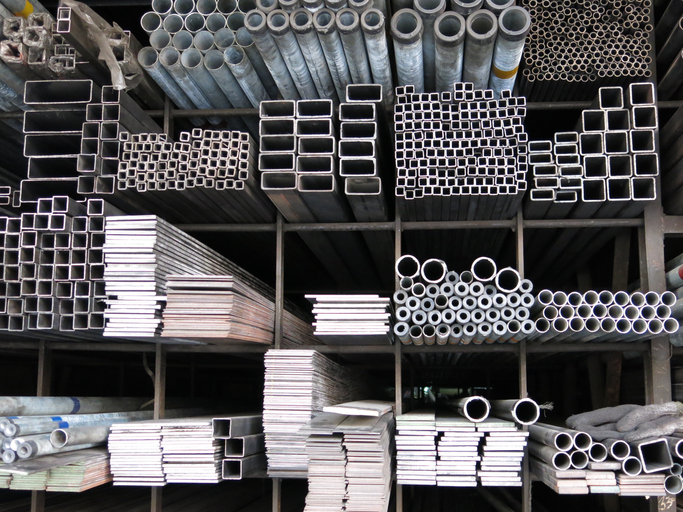

As the name implies, this process creates everything you can think of, be it stairway railings, vehicle components, or construction equipment. The main raw materials used in metal fabrication are formed and expanded metal, plate metal, tube stock, welding rod/wire, and sectional metal.

These raw materials are meant for specific applications, and therefore, you can create everything imaginable. Here’s how the raw materials get utilized for different applications:

- For engineering and construction projects, metal fabricators mainly use sectional metals, including bars and rods, the Z shape, the I-beam, and structural sections.

- Expanded metal sheets are ideal for fabricating screen doors, outdoor furniture, and safety guards on machines to prevent contact with hot surfaces.

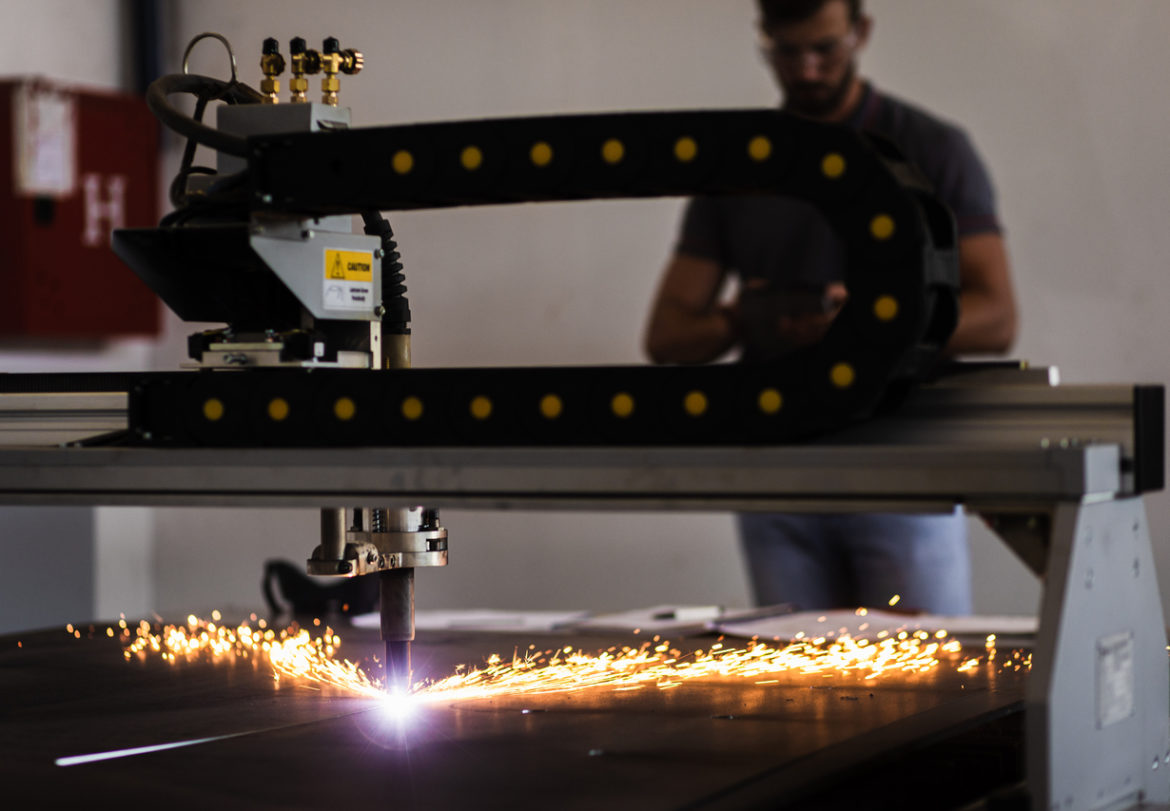

The Process Involves More than Cutting and Welding

Many people think that custom metal fabrication is all about cutting and welding. However, metal fabrication shops use various processes and techniques to ensure that the final product meets the desired standards. These include forging, punching, brazing, and spinning. A specialty shop can also implement advanced procedures such as chipping, casting, powder metallurgy, and powder coating.

The Metal Fabrication Process is Complex

Looking at custom metal fabricators doing their job, you might think that it’s easy. However, a lot goes into the process. For starters, sketches must be drawn and engineered for a particular idea in mind before being presented to the metal fabrication company.

A team of experts will study the sketches to determine whether the idea is feasible and the type of materials needed. It’s only after a consensus regarding design, cost, and execution are reached that the fabrication work can start. The custom metal fabrication process is generally broken down into three major steps, which are:

- Project design

- Fabrication of different individual components

- Assembling the individual pieces into the final product

The metal fabrication process is complex, highlighting why you should rely on experts whenever you have a project. The main advantage of choosing a one-stop metal fabrication shop is that experts will do everything under one roof. The centralization of all the processes involved guarantees the quality of the final product. It also ensures that the final product is delivered within the stipulated timeframe.

Final Words

The quality of your metal fabrication project depends on the shop you choose. At Profusion, we know all about custom metal fabrication, and our experts have the experience to bring all your ideas to life. We leverage our expertise to create quality products for our customers. Contact us today to learn more about our services.