Benefits of Sheet Metal Fabrication

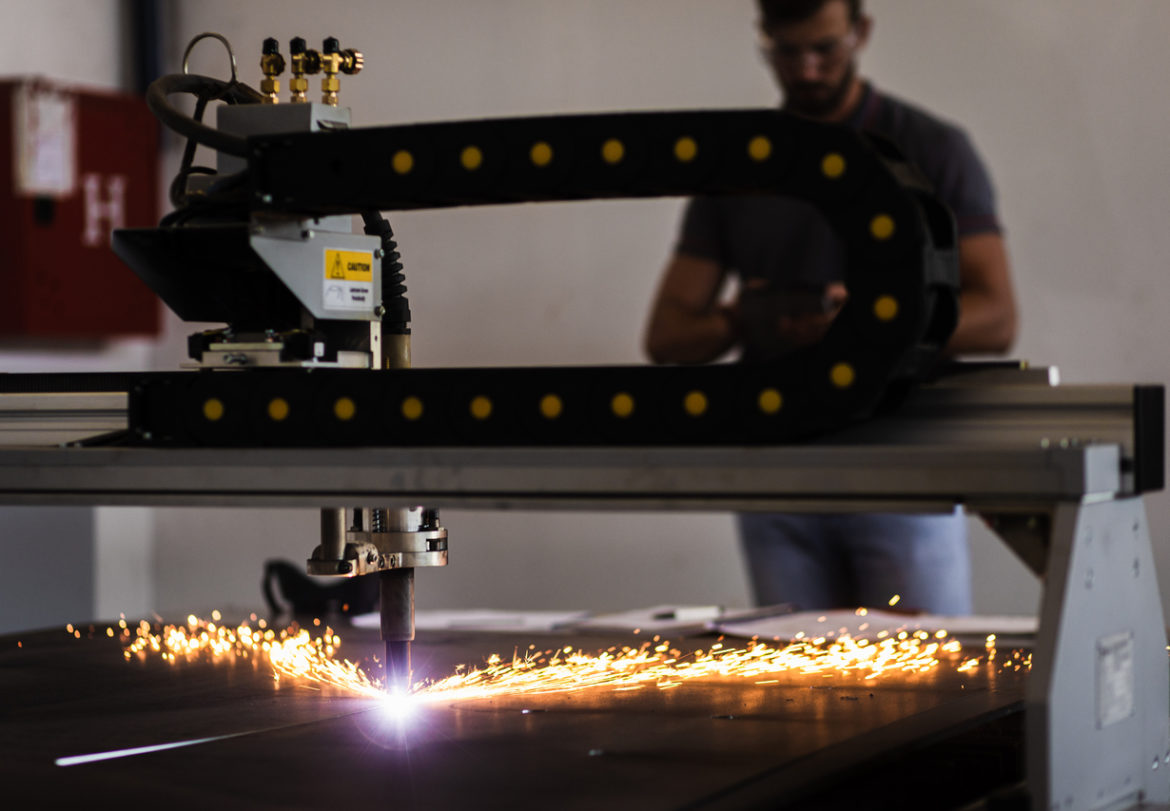

There are different technologies for sheet metal fabrication. However, none are faster, efficient, and more precise than laser cutting.

Laser cutting works by melting the metal using a high-powered laser beam. The technology solved the inadequacies of manual cutting and is used in industries such as aerospace, automotive, and electronics.

Laser cutting comes with unique advantages that make it a good fit for sheet metal fabrication.

Precision

Laser cutting technology is highly precise, up to 25 microns, which is narrower than a strand of hair. It also has an accuracy of about 10 micrometers with repeatability of about 5 micrometers.

Other cutting technologies produce a lot of heat that can damage the metal being cut. However, laser cutting machines only heat a small area of the metal undergoing fabrication. Therefore, there is minimal risk of damage to the material.

Besides, the laser cutting machines have a jet system that feeds compressed air, which expels the evaporated residue. This expelling of residue further enhances the cutting accuracy and quality.

Ultimately, laser cutting provides accurate, smooth, and clean cuts.

Versatility

Laser cutting performs all your metal fabrication needs:

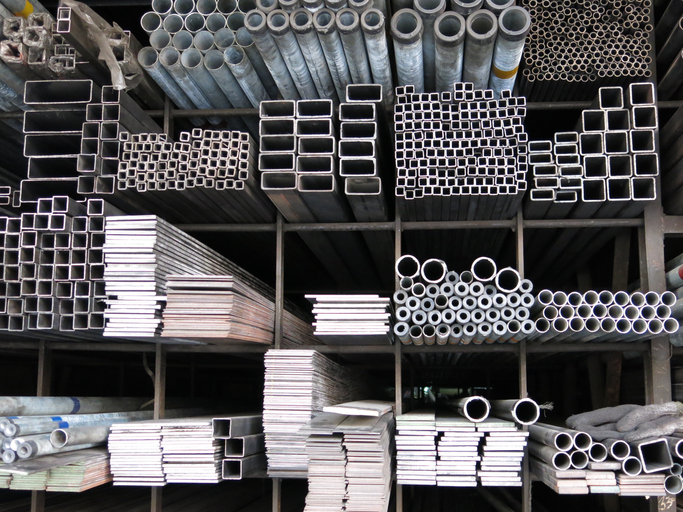

- The laser beam can cut a wide range of flat, profiled, and tubed materials, including stainless steel, mild steel, aluminum, and even wood and plastics.

- With laser cutting, you can achieve any design specification, from delicate and small designs to large and complex creations.

- Laser cutting can also be used for a wide range of fabrication services, including marking, engraving, and drilling. The controlled heat output and intensity allow the different applications of laser cutting.

Speed

Laser beams cut through metal fast. Typically, laser technology will cut through 1mm thick mild steel at the speed of 18m/min. If you are working with 3mm thick steel, you can expect speeds of up to 4.5m/min.

However, you have to optimize the speed and power of the laser nozzle, depending on what you are doing. For instance, while engraving, you can use the maximum speed and set the power level depending on the darkness level your project needs. On the other hand, when cutting, the maximum speed might be too fast to cut all the way through depending on the thickness of the metal.

You can reduce cutting times by using multiple lasers simultaneously or multi-head lasers.

Efficiency

Laser cutters use a beam, meaning they do not make direct contact with the material. Therefore, they do not wear down; neither does work stop for retooling or replacement of components. Laser cutters can work for long hours, which improves efficiency.

Additionally, these machines work through automation. All you have to do is enter codes on a computer, and the machine will start working with precision and produce work with little or no defects. So, you can improve efficiency by leaving the machine to work overnight when there is no one around.

Consistency

Automation also eliminates human error. Therefore, you get accurate and consistent results. Duplicating a design multiple times is a breeze with laser cutting.

Consistency and accuracy only require the right software and quality laser cutting machines and parts.

Cost-effectiveness

In the long run, laser cutting is cheaper than other sheet metal fabrication methods. For starters, it does not require multiple human operators, meaning it saves you labor costs.

Then, there is the improved speed and efficiency. Remember, time is money. Plus, the improved speed and efficiency do not necessarily translate to more energy consumption. Combined with energy-efficient technology, laser cutters use small amounts of energy.

Additionally, laser cutters require little maintenance.

Versatility, precision and accuracy, speed, efficiency, and consistent results at a relatively low cost – what more could you want from sheet metal fabrication technology? Contact us at ProfusionUSA now for more information on laser cutting.